Owner: MadTree Brewing

Location: Cincinnati, OH

Project Description:

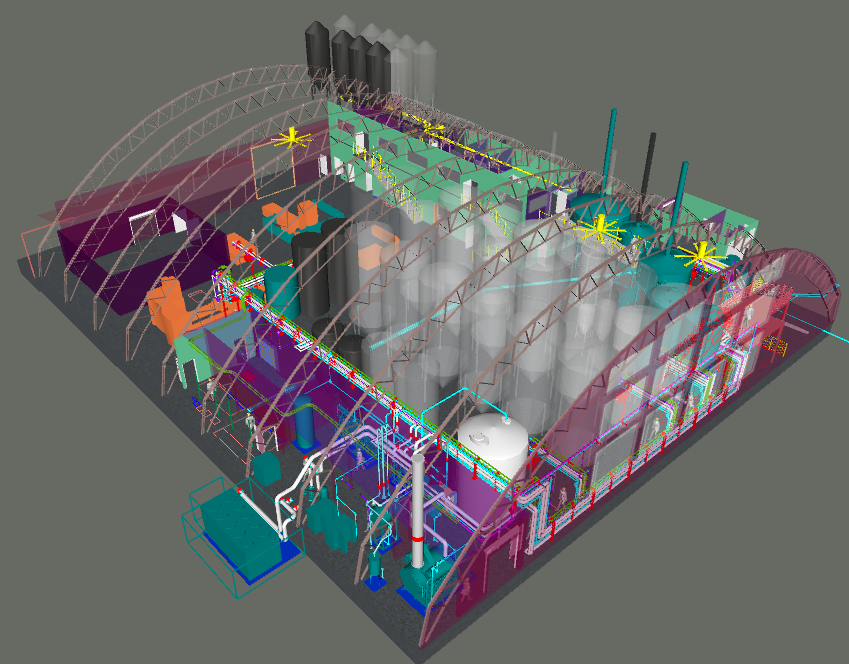

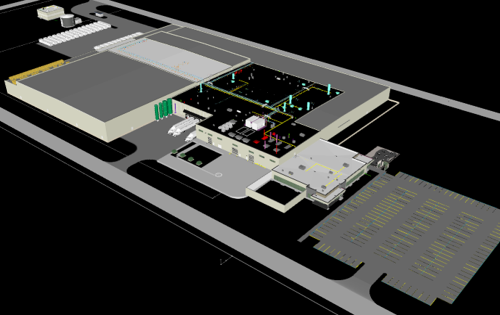

ThermalTech Engineering has worked as MadTree’s engineering partner since it’s initial planning and brewery location in 2012. ThermalTech worked with MadTree to advance the production capabilities with a new location featuring a new 100 BBL brewhouse provided by W.M. Sprinkman. A 15 BBL pilot brewhouse was later constructed and controls furnished by ThermalTech to allow the centralization of operations to the new facility.

ThermalTech delivered a turnkey process utilities system including utilities, production controls, and packaging controls integration.

A complete process control system was designed, installed, programmed, and commissioned for the entire brewery. The controls were delivered on a Rockwell Automation PAC platform and Inductive Automation Ignition HMI & Historian. Recipe management allows for pre-planning and batching of metering out weighed ingredients to the mill, crushing, mash in, lautering, boil, and whirlpool system automation, and then through fermentation, brite/carbonation to be ready for packaging through a single HMI. The control system also integrates with MadTree’s production planning, material ordering, and other systems through database integration. The packaging system including all conveyance, de-palletizer, filler, seamer, fill check, 6-packer, and case-erector were integrated into a master controller for total line management and visualization.

The utilities designed and installed by ThermalTech include: chilled water, steam, RO water generation/storage/UV sanitization, compressed air, and power distribution. All systems are centrally monitored and controlled by a Rockwell PAC and integrated into the facility-wide SCADA system including historian trending to allow for close monitoring during production as well as ensuring that product in fermentation is well controlled. System alarming is configured in multiple tiers of trouble including email and SMS messaging.